Business inventory for new business partnership – Establishing a solid business inventory management system is crucial for the success of any new business partnership. This guide provides comprehensive guidance on creating an accurate inventory, selecting the appropriate valuation method, and implementing effective optimization strategies to minimize waste and maximize efficiency.

Additionally, we’ll explore the importance of inventory control procedures, regular audits, and reporting to ensure accountability and informed decision-making. By addressing the unique challenges and opportunities of inventory management in partnerships, this guide empowers businesses to foster collaboration, resolve potential conflicts, and achieve inventory management excellence.

Business Inventory Management for New Partnerships

Establishing a comprehensive inventory management system is crucial for the success of any new business partnership. It provides a clear understanding of the assets and liabilities of the partnership, enabling informed decision-making and efficient operations.

Creating an Accurate Inventory

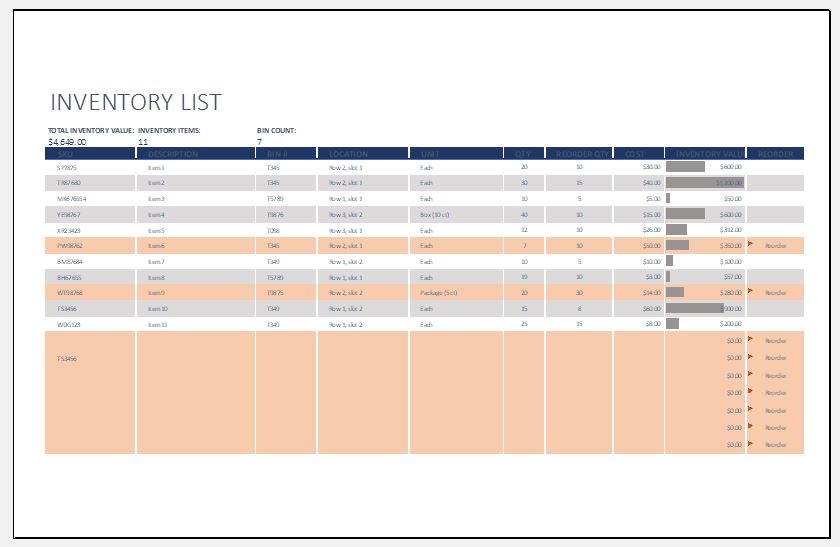

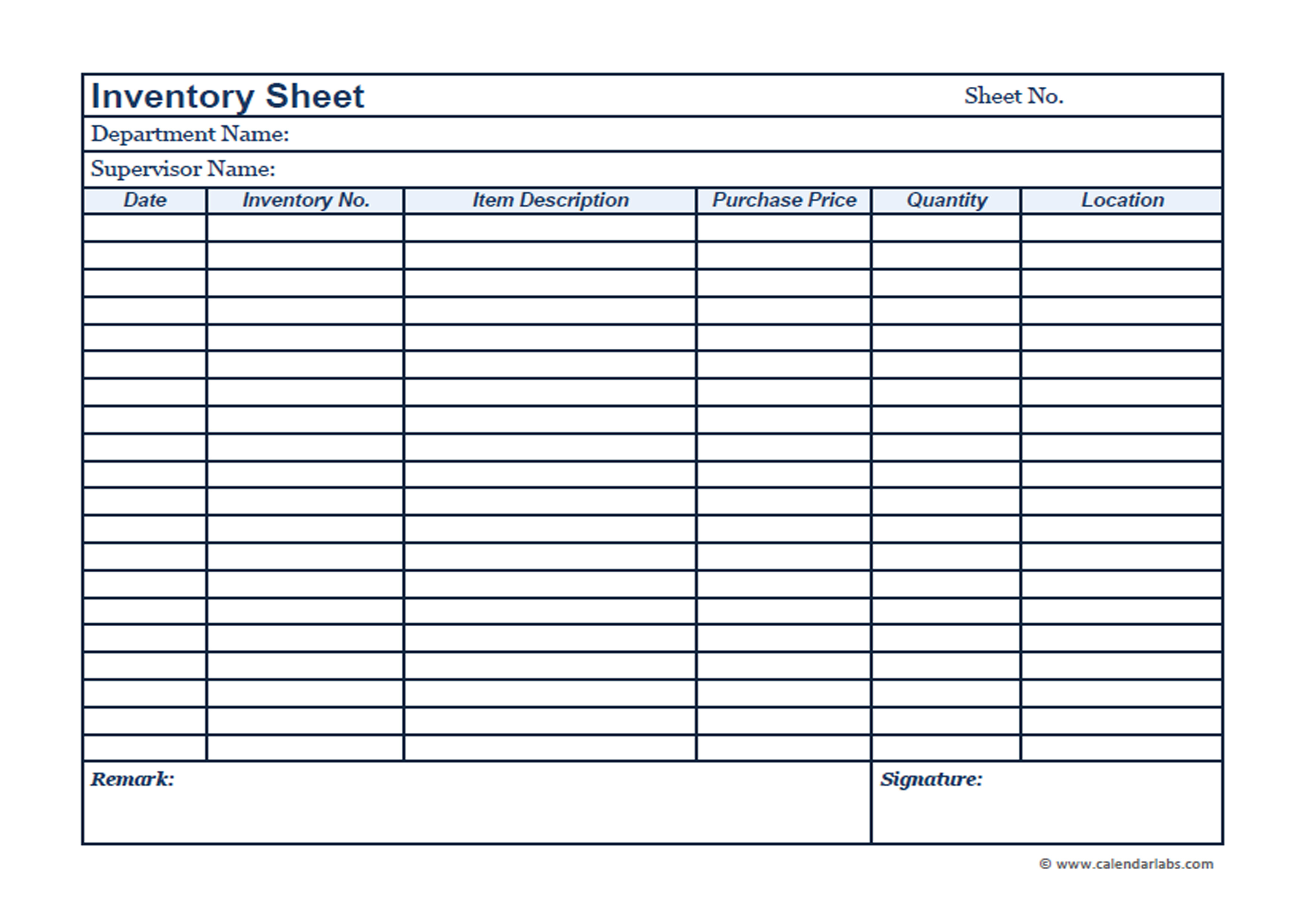

An accurate inventory reflects the physical assets and financial obligations of the partnership. It should include a detailed list of all items, their quantities, values, and locations. Regular physical counts and reconciliations with accounting records ensure the accuracy and reliability of the inventory.

Tracking Inventory Levels

Effective inventory management involves tracking inventory levels to prevent overstocking or shortages. Real-time inventory tracking systems provide visibility into stock levels, allowing for timely replenishment and preventing disruptions in operations.

Ensuring Accountability

Establishing clear accountability for inventory management is essential. Assign specific responsibilities to individuals or teams for maintaining inventory records, conducting physical counts, and managing stock levels. This ensures that everyone is aware of their roles and contributes to the accuracy and efficiency of the inventory management system.

Inventory Valuation Methods

Inventory valuation methods are crucial for determining the value of a business’s inventory, which directly impacts financial statements and decision-making. Several methods exist, each with its advantages and disadvantages. Understanding these methods and selecting the most appropriate one is essential for accurate financial reporting and informed decision-making.

Specific Identification Method

Under the specific identification method, each inventory item is tracked and valued individually. This method provides the most accurate valuation but can be time-consuming and impractical for large inventories.

Advantages:

- Provides the most precise valuation of inventory

- Useful for unique or high-value items

Disadvantages:

- Labor-intensive and time-consuming

- Not suitable for large or rapidly changing inventories

First-In, First-Out (FIFO) Method

FIFO assumes that the oldest inventory items are sold first. The cost of goods sold is based on the cost of the earliest purchased items. This method is relatively easy to apply and results in a lower cost of goods sold in inflationary periods.

Advantages:

- Easy to implement and manage

- Results in lower cost of goods sold during inflation

Disadvantages:

- May not accurately reflect the current market value of inventory

- Can lead to overstatement of inventory value during deflationary periods

Last-In, First-Out (LIFO) Method

LIFO assumes that the most recently purchased inventory items are sold first. The cost of goods sold is based on the cost of the latest purchased items. This method results in a higher cost of goods sold in inflationary periods.

Advantages:

- Can reduce taxable income during inflationary periods

- Provides a more conservative valuation of inventory

Disadvantages:

- May not accurately reflect the current market value of inventory

- Can lead to understatement of inventory value during deflationary periods

Weighted Average Cost Method, Business inventory for new business partnership

The weighted average cost method calculates the average cost of inventory based on all purchases made during a period. This method provides a more stable valuation than FIFO or LIFO and is often used for large, rapidly changing inventories.

Advantages:

- Provides a more stable and consistent valuation

- Relatively easy to implement and manage

Disadvantages:

- May not accurately reflect the current market value of inventory

- Can be more complex to calculate than FIFO or LIFO

Selecting the Most Appropriate Method

The most appropriate inventory valuation method for a new business partnership depends on several factors, including:

- Nature of the inventory

- Volume and turnover of inventory

- Financial reporting objectives

- Tax implications

For businesses with unique or high-value items, the specific identification method may be suitable. For businesses with large or rapidly changing inventories, the weighted average cost method or FIFO method may be more practical. Businesses operating in inflationary or deflationary environments may consider LIFO or FIFO methods to minimize tax liability or provide a more conservative valuation.

Inventory Optimization Strategies

Optimizing inventory levels is crucial for minimizing waste and maximizing efficiency in business partnerships. By employing effective strategies, businesses can streamline their inventory management processes, reduce costs, and enhance profitability.

Forecasting Demand

Accurate demand forecasting is essential for optimizing inventory levels. Businesses can leverage historical sales data, market trends, and industry analysis to predict future demand. This information enables them to make informed purchasing decisions, ensuring they have the right inventory at the right time.

- Use statistical forecasting models to analyze historical demand patterns.

- Consider seasonal fluctuations and external factors that may impact demand.

- Collaborate with suppliers to gain insights into market trends and potential disruptions.

Safety Stock Management

Safety stock serves as a buffer against unexpected fluctuations in demand or supply. Determining the optimal safety stock level involves balancing the risk of stockouts with the cost of holding excess inventory.

- Use formulas such as the Reorder Point (ROP) and Safety Stock Level (SSL) to calculate appropriate safety stock levels.

- Monitor inventory levels regularly and adjust safety stock levels based on demand patterns and lead times.

li>Consider using safety stock pools to optimize inventory across multiple locations or product lines.

Inventory Turnover

Inventory turnover measures how efficiently inventory is being used. High inventory turnover indicates that inventory is moving quickly, reducing the risk of obsolescence and waste.

- Calculate inventory turnover by dividing the cost of goods sold (COGS) by the average inventory value.

- Aim for a high inventory turnover rate to minimize carrying costs and maximize profitability.

- Identify and address bottlenecks in the inventory management process to improve turnover.

Vendor Management

Effective vendor management is crucial for ensuring timely inventory replenishment and minimizing disruptions.

- Establish clear communication channels with vendors to facilitate timely order placement and delivery.

- Negotiate favorable terms, including discounts, lead times, and minimum order quantities.

- Monitor vendor performance and identify opportunities for improvement in delivery reliability and quality.

Inventory Management Software

Inventory management software streamlines the process of tracking and managing inventory, providing businesses with real-time visibility into their stock levels. This allows them to optimize inventory levels, reduce waste, and improve customer satisfaction.There are numerous inventory management software solutions available, each with its own unique features and benefits.

Some of the most popular options include:

- NetSuite: A comprehensive ERP system that includes inventory management functionality.

- SAP Business One: Another ERP system that offers inventory management capabilities.

- Fishbowl Inventory: A standalone inventory management software solution.

- QuickBooks Commerce: An e-commerce platform that includes inventory management features.

- Zoho Inventory: A cloud-based inventory management software solution.

When selecting inventory management software for a new business partnership, it is important to consider the following factors:

- The size and complexity of your inventory.

- Your budget.

- The level of integration you need with other business systems.

- The features and functionality that are important to you.

By carefully considering these factors, you can choose the right inventory management software solution to help your new business partnership succeed.

Inventory Audits

Conducting regular inventory audits is crucial for businesses, especially for new partnerships. It ensures accurate inventory records, reduces losses, and helps businesses make informed decisions about inventory management.

There are several types of inventory audits, each with its own benefits:

- Cycle counting:Involves counting a portion of inventory on a regular basis, typically weekly or monthly. It helps identify discrepancies early and prevent larger issues.

- Spot audits:Random audits conducted at unexpected times to check the accuracy of inventory records and deter theft.

- Full audits:Comprehensive audits that involve counting all inventory items at once. They are typically conducted annually or semi-annually.

To conduct an effective inventory audit, follow these steps:

- Plan and prepare:Determine the scope of the audit, assemble a team, and gather necessary tools.

- Count and verify:Physically count all inventory items and compare them to inventory records.

- Investigate discrepancies:Analyze any discrepancies between the physical count and inventory records to identify root causes.

- Document and report:Record the audit results, including any discrepancies and recommendations for improvement.

- Follow up:Implement corrective actions based on the audit findings to improve inventory accuracy and efficiency.

Inventory Reporting

Inventory reporting is a critical aspect of inventory management that provides valuable insights into the status and performance of a company’s inventory. By analyzing inventory reports, businesses can make informed decisions to optimize inventory levels, reduce costs, and improve operational efficiency.

Types of Inventory Reports

Various types of inventory reports can be generated, each serving a specific purpose:

- Inventory Valuation Report:Determines the total value of inventory on hand, which is crucial for financial reporting and tax purposes.

- Stock Status Report:Provides a snapshot of the quantity and location of each inventory item, enabling businesses to track stock levels and prevent shortages.

- Inventory Turnover Report:Calculates the rate at which inventory is sold and replaced, indicating the efficiency of inventory management.

- Inventory Ageing Report:Identifies slow-moving or obsolete inventory, allowing businesses to clear out old stock and reduce losses.

- ABC Analysis Report:Classifies inventory items based on their value and usage, helping businesses prioritize inventory management efforts.

- Inventory Discrepancy Report:Highlights differences between physical inventory counts and records, enabling businesses to identify and address inventory shrinkage.

Inventory Management in the Context of a New Business Partnership: Business Inventory For New Business Partnership

Managing inventory in a new business partnership presents unique challenges and opportunities. Partners must navigate potential conflicts and ensure effective collaboration to optimize inventory management practices.

Addressing Potential Conflicts

- Divergent perspectives:Partners may have different experiences, values, and goals, leading to differing views on inventory management.

- Communication barriers:Misunderstandings or lack of communication can hinder inventory coordination and decision-making.

- Unclear roles and responsibilities:Undefined roles can create confusion and overlap in inventory management tasks.

Ensuring Effective Collaboration

- Establish clear communication channels:Regular meetings, open dialogue, and defined communication protocols foster transparency and understanding.

- Define roles and responsibilities:Assign specific inventory management tasks to each partner, ensuring accountability and avoiding overlap.

- Seek professional guidance:Consult with inventory management experts or business advisors to provide objective perspectives and best practices.

Case Studies of Successful Inventory Management Practices

- Partnership A:Implemented a centralized inventory management system, enabling real-time visibility and coordination.

- Partnership B:Adopted a just-in-time inventory strategy, reducing inventory carrying costs and improving cash flow.

- Partnership C:Utilized advanced inventory optimization software to forecast demand and optimize stock levels.

Last Recap

Effective inventory management is a cornerstone of successful new business partnerships. By following the strategies Artikeld in this guide, businesses can establish a robust system that accurately reflects their assets and liabilities, optimizes inventory levels, and supports informed decision-making. This guide provides a comprehensive roadmap for managing inventory in partnerships, ensuring transparency, accountability, and ultimately driving business growth.

FAQ Summary

What are the key benefits of establishing a comprehensive inventory management system?

Improved accuracy, reduced waste, enhanced efficiency, increased transparency, and better decision-making.

How do I select the most appropriate inventory valuation method for my partnership?

Consider factors such as industry norms, inventory turnover rate, and the level of precision required.

What strategies can I implement to optimize inventory levels and minimize waste?

Use data analysis to forecast demand, implement just-in-time inventory systems, and negotiate favorable supplier terms.