Embarking on a journey into the realm of business inventory programs, we delve into the intricacies of inventory management, exploring its significance in business operations and the diverse roles of inventory types. Prepare to unravel the secrets of perpetual, periodic, and hybrid inventory systems, contrasting their features and advantages to guide your informed decision-making.

Unveiling the benefits of implementing an inventory program, we showcase its prowess in enhancing inventory accuracy, minimizing waste, and optimizing stock levels. Real-world data and case studies illuminate the transformative impact of these programs on business outcomes, painting a compelling picture of their value.

Inventory Management Overview

Inventory management is the backbone of any business operation, regardless of its size or industry. It involves the planning, tracking, and controlling of inventory levels to ensure that the right amount of products are available at the right time, while minimizing costs and waste.

Inventory management plays a crucial role in supply chains, ensuring that raw materials are available for production, finished goods are available for sale, and customer demand is met efficiently. By optimizing inventory levels, businesses can improve their cash flow, reduce storage costs, and enhance customer satisfaction.

Types of Inventory

There are various types of inventory that businesses may hold, each with its own role in the supply chain:

- Raw materials: These are the basic components or ingredients used in the production process.

- Work-in-progress (WIP): These are partially finished goods that are still in the production process.

- Finished goods: These are completed products that are ready for sale to customers.

- Safety stock: This is additional inventory held as a buffer to protect against unexpected demand or supply disruptions.

Types of Business Inventory Programs

Inventory management is essential for any business that sells or produces physical goods. Choosing the right inventory program can help you keep track of your inventory levels, optimize your ordering process, and avoid stockouts.

There are three main types of inventory programs: perpetual inventory systems, periodic inventory systems, and hybrid systems.

Perpetual Inventory Systems

Perpetual inventory systems track inventory levels in real-time. This means that every time an item is purchased or sold, the inventory level is updated. Perpetual inventory systems are typically more expensive than periodic inventory systems, but they offer a number of advantages, including:

- Improved accuracy: Perpetual inventory systems are more accurate than periodic inventory systems because they track inventory levels in real-time.

- Better visibility: Perpetual inventory systems provide better visibility into inventory levels, which can help you avoid stockouts and make better decisions about ordering.

- Reduced waste: Perpetual inventory systems can help you reduce waste by tracking inventory levels and identifying items that are not selling well.

Periodic Inventory Systems

Periodic inventory systems track inventory levels at regular intervals, such as monthly or quarterly. This means that the inventory level is not updated every time an item is purchased or sold. Periodic inventory systems are typically less expensive than perpetual inventory systems, but they offer a number of disadvantages, including:

- Reduced accuracy: Periodic inventory systems are less accurate than perpetual inventory systems because they do not track inventory levels in real-time.

- Poor visibility: Periodic inventory systems provide poor visibility into inventory levels, which can lead to stockouts and poor decision-making.

- Increased waste: Periodic inventory systems can lead to increased waste because they do not track inventory levels and identify items that are not selling well.

Hybrid Inventory Systems

Hybrid inventory systems combine features of both perpetual and periodic inventory systems. For example, a hybrid inventory system might track inventory levels in real-time for high-value items and track inventory levels at regular intervals for low-value items.

Hybrid inventory systems offer a number of advantages, including:

- Improved accuracy: Hybrid inventory systems are more accurate than periodic inventory systems because they track inventory levels in real-time for high-value items.

- Better visibility: Hybrid inventory systems provide better visibility into inventory levels than periodic inventory systems because they track inventory levels in real-time for high-value items.

- Reduced waste: Hybrid inventory systems can help reduce waste by tracking inventory levels and identifying items that are not selling well.

Benefits of Implementing an Inventory Program

Inventory programs are essential tools for businesses of all sizes. They can help businesses improve inventory accuracy, reduce waste, and optimize stock levels. This can lead to significant cost savings and improved profitability.

Inventory programs can improve inventory accuracy by providing businesses with real-time visibility into their inventory levels. This can help businesses avoid overstocking or understocking items, which can lead to lost sales or wasted inventory.

Inventory programs can also help businesses reduce waste by identifying and tracking slow-moving items. This information can help businesses make informed decisions about which items to discontinue or sell at a discount.

Finally, inventory programs can help businesses optimize stock levels by providing them with insights into demand patterns. This information can help businesses ensure that they have the right amount of inventory on hand to meet customer demand without overstocking.

Case Study

A recent study by the Aberdeen Group found that businesses that implemented inventory programs saw a 25% reduction in inventory costs and a 10% increase in sales.

Considerations for Choosing an Inventory Program

Selecting the right inventory program is crucial for efficient inventory management. Several factors need to be considered to ensure the chosen solution aligns with the specific needs of the business.

The following guidelines will assist in evaluating and comparing different software solutions:

Business Size and Industry

- Small businesses may require a simple, user-friendly program with basic features.

- Larger businesses with complex inventory requirements need robust software with advanced functionality.

- Different industries have specific inventory management needs (e.g., manufacturing, retail, healthcare).

Inventory Complexity

- Consider the number of items, SKUs, and variations managed.

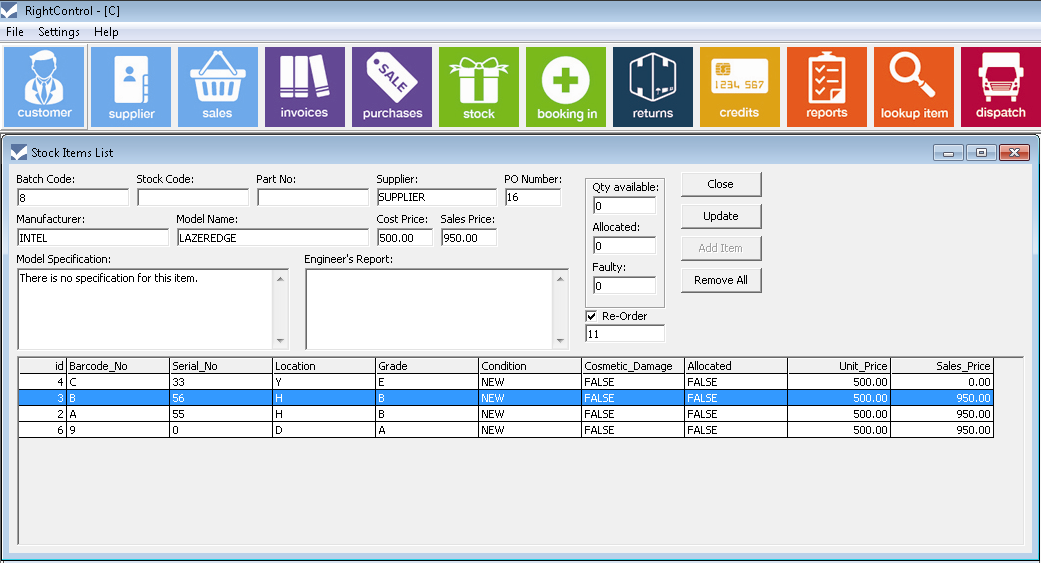

- Assess the need for features like multi-location inventory tracking, lot/serial number tracking, and expiration date management.

- Determine if the inventory program can handle the volume and complexity of the business’s inventory.

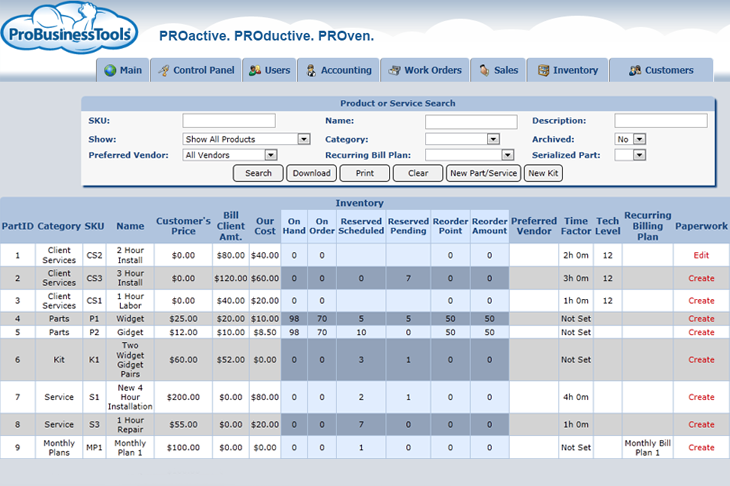

Software Features and Functionality

- Identify the core features required, such as inventory tracking, order management, and reporting.

- Consider additional features like barcode scanning, mobile access, and integration with other business systems.

- Evaluate the user interface, ease of use, and training requirements.

Scalability and Flexibility

- Ensure the program can grow with the business and accommodate future expansion.

- Consider the ability to add users, locations, and products without significant cost or effort.

- Assess the flexibility of the software to adapt to changing business processes and requirements.

Cost and Support

- Determine the upfront cost, subscription fees, and any additional expenses associated with the software.

- Evaluate the level of customer support provided and its availability.

- Consider the return on investment (ROI) and the potential benefits of implementing the inventory program.

Best Practices for Inventory Management

Effective inventory management is crucial for optimizing business operations and profitability. Implementing best practices can help businesses improve accuracy, reduce costs, and enhance customer satisfaction.

Key best practices include:

Inventory Forecasting, Business inventory program

Accurate forecasting is essential for maintaining optimal inventory levels. Businesses can leverage historical data, demand patterns, and market trends to predict future demand. This information helps them plan for seasonal fluctuations, promotions, and supply chain disruptions.

Cycle Counting

Cycle counting is a regular process of physically verifying inventory levels against records. It helps identify discrepancies, prevent shrinkage, and ensure accurate inventory data. By conducting regular cycle counts, businesses can maintain a clear understanding of their inventory and make informed decisions.

Safety Stock Levels

Safety stock refers to the extra inventory held to buffer against unexpected demand fluctuations or supply chain disruptions. Determining appropriate safety stock levels involves considering factors such as lead times, demand variability, and service levels. By maintaining adequate safety stock, businesses can minimize the risk of stockouts and meet customer demand.

Optimizing Inventory Turnover

Inventory turnover measures how quickly inventory is sold and replaced. High turnover rates indicate efficient inventory management and reduced carrying costs. Businesses can improve turnover by:

- Managing inventory levels closely

- Using just-in-time inventory systems

- Reducing lead times

Minimizing Carrying Costs

Carrying costs include expenses associated with holding inventory, such as storage, insurance, and obsolescence. Businesses can minimize these costs by:

- Negotiating favorable terms with suppliers

- Storing inventory efficiently

- Selling slow-moving items at a discount

Integration with Other Business Systems

Inventory programs can be seamlessly integrated with other critical business systems to streamline operations and enhance data accuracy.

Integrating inventory data with accounting software provides a comprehensive view of financial transactions related to inventory management. This integration automates tasks such as cost tracking, invoicing, and purchase order processing, reducing errors and improving efficiency.

Enterprise resource planning (ERP) systems offer a central platform for managing various business processes, including inventory management. Integrating inventory programs with ERP systems enables real-time visibility into inventory levels, facilitates demand planning, and optimizes supply chain management.

Point-of-sale (POS) systems capture sales transactions and provide valuable data for inventory management. By integrating inventory programs with POS systems, businesses can automatically update inventory levels based on sales, reducing the risk of overstocking or understocking.

Benefits of Integrating Inventory Data

Integrating inventory data across different systems offers numerous benefits, including:

- Improved data accuracy and consistency

- Enhanced visibility and control over inventory levels

- Automated and streamlined business processes

- Reduced errors and increased efficiency

- Better decision-making based on real-time data

Emerging Trends in Inventory Management

The field of inventory management is undergoing a significant transformation, driven by the emergence of cutting-edge technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT). These technologies are revolutionizing inventory management practices, enabling businesses to achieve greater efficiency, accuracy, and cost-effectiveness.

Artificial Intelligence (AI)

- AI algorithms can analyze vast amounts of data to identify patterns and trends, enabling businesses to make more informed decisions about inventory levels, reorder points, and safety stock.

- AI-powered inventory management systems can automate tasks such as forecasting demand, optimizing stock levels, and generating purchase orders, freeing up human resources for more strategic activities.

Machine Learning (ML)

- ML algorithms can learn from historical data and improve their performance over time, providing businesses with increasingly accurate inventory predictions.

- ML-based inventory management systems can detect anomalies in inventory data, such as sudden spikes in demand or unusual patterns of shrinkage, enabling businesses to respond promptly to potential issues.

Internet of Things (IoT)

- IoT devices, such as sensors and RFID tags, can provide real-time visibility into inventory levels, enabling businesses to track the movement of goods throughout the supply chain.

- IoT-enabled inventory management systems can automate inventory replenishment, ensuring that businesses always have the right amount of stock on hand.

Final Review

In conclusion, business inventory programs stand as indispensable tools for businesses seeking to streamline their inventory management practices. Through careful consideration of key factors, businesses can harness the power of these programs to achieve inventory optimization, reduce costs, and gain a competitive edge. As technology continues to advance, emerging trends in inventory management promise even greater efficiency and innovation, empowering businesses to navigate the complexities of the modern supply chain.

FAQ: Business Inventory Program

What are the key benefits of implementing a business inventory program?

Implementing a business inventory program offers numerous benefits, including improved inventory accuracy, reduced waste, optimized stock levels, enhanced forecasting capabilities, and streamlined operations.

How do I choose the right inventory program for my business?

Selecting the appropriate inventory program requires careful consideration of factors such as business size, industry, inventory complexity, and budget. Evaluating different software solutions and comparing their features, ease of use, and cost is crucial.

What are some best practices for inventory management?

Effective inventory management practices include regular inventory audits, cycle counting, safety stock maintenance, and inventory forecasting. Optimizing inventory turnover and minimizing carrying costs are also essential.