Inventory software for business is revolutionizing the way companies manage their inventory, offering a myriad of benefits that streamline operations, reduce costs, and enhance customer satisfaction. From real-time tracking to advanced reporting, these tools empower businesses to gain unparalleled visibility and control over their inventory, unlocking new levels of efficiency and growth.

In this comprehensive guide, we delve into the world of inventory software for business, exploring its key features, benefits, and implementation strategies. Discover how this transformative technology can transform your inventory management practices and drive your business towards success.

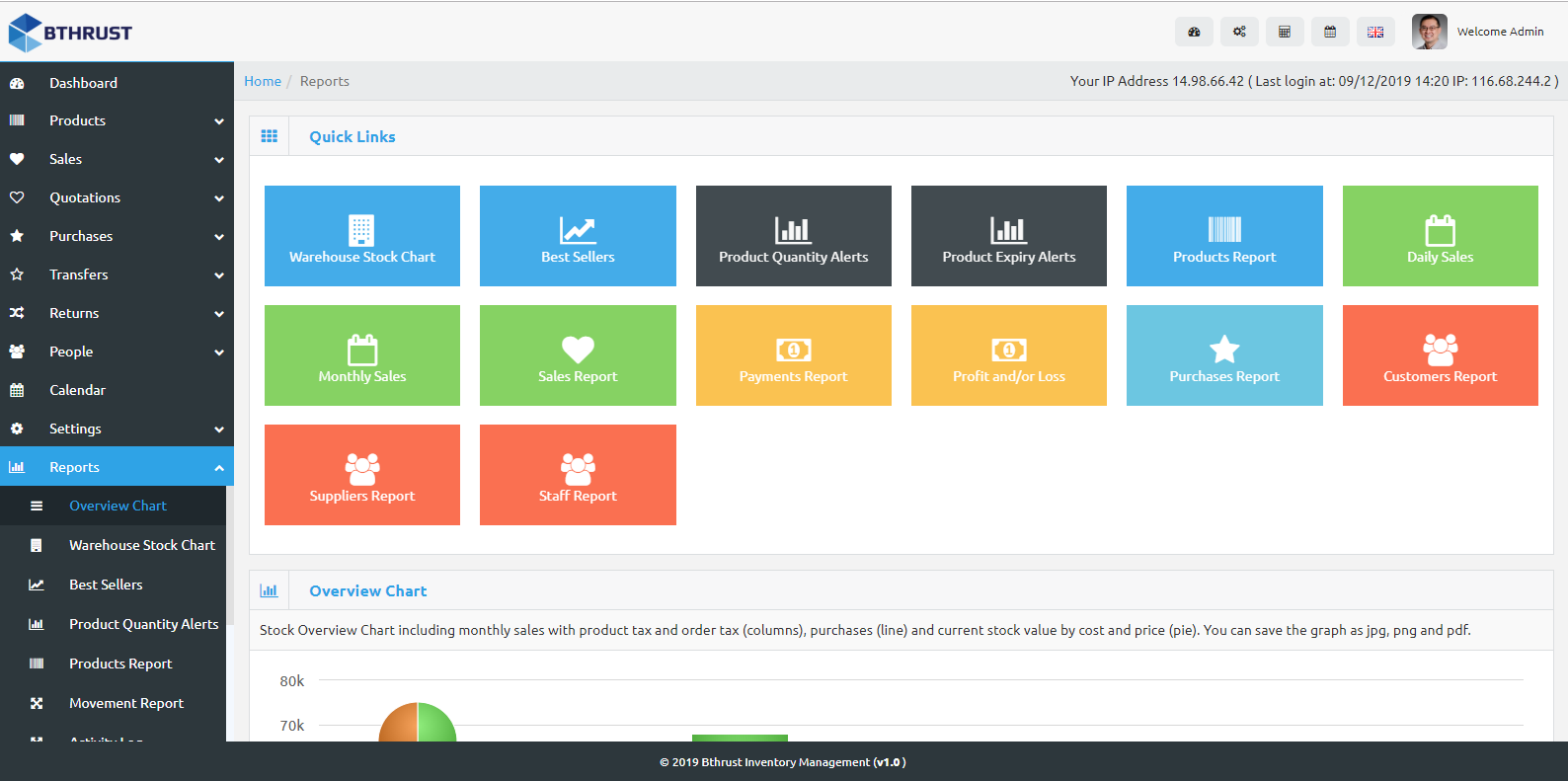

Inventory Management Software Overview

Inventory management software is a tool that helps businesses track and manage their inventory levels. This can be a valuable asset for businesses of all sizes, as it can help them to reduce costs, improve efficiency, and make better decisions about their inventory.

There are many different types of inventory management software available, each with its own set of features and functionalities. Some of the most common features include:

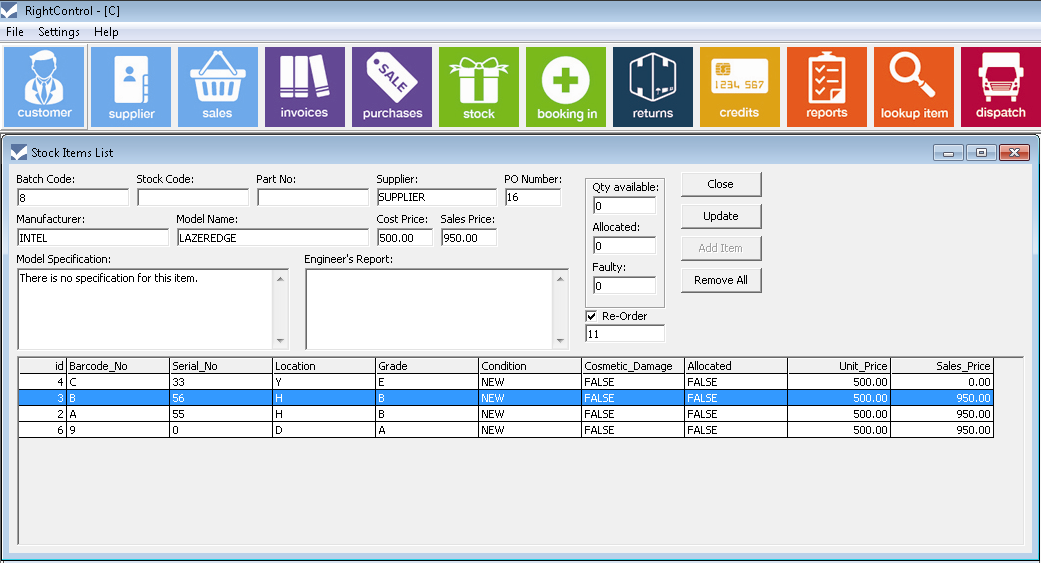

- Inventory tracking: This feature allows businesses to track the quantity of each item in their inventory, as well as its location and status.

- Reorder point management: This feature helps businesses to determine when to reorder items based on their current inventory levels and usage patterns.

- Inventory forecasting: This feature helps businesses to predict future demand for items based on historical data and current trends.

- Reporting: This feature allows businesses to generate reports on their inventory levels, usage patterns, and other key metrics.

Inventory management software can be a valuable tool for businesses of all sizes. By using this software, businesses can improve their inventory management practices, reduce costs, and make better decisions about their inventory.

Benefits of Inventory Management Software

Inventory management software provides numerous advantages to businesses, leading to significant cost savings, improved efficiency and productivity, reduced waste, and enhanced customer satisfaction.

Cost-Saving Advantages

Inventory management software automates inventory tracking and management tasks, reducing the need for manual labor and eliminating human errors. This streamlining of processes leads to lower labor costs and increased accuracy, resulting in significant cost savings.

Improved Efficiency and Productivity

By providing real-time visibility into inventory levels, inventory management software enables businesses to optimize their inventory management processes. This includes reducing stockouts, preventing overstocking, and streamlining order fulfillment. As a result, businesses can operate more efficiently and increase their productivity.

Reduced Waste

Inventory management software helps businesses identify and reduce waste by providing insights into inventory levels and trends. This enables businesses to make informed decisions about inventory levels, preventing overstocking and reducing the risk of spoilage or obsolescence. By optimizing inventory levels, businesses can minimize waste and improve their bottom line.

Improved Customer Satisfaction

Inventory management software plays a crucial role in improving customer satisfaction by ensuring product availability and reducing the likelihood of stockouts. By providing real-time visibility into inventory levels, businesses can accurately fulfill customer orders, reduce shipping delays, and enhance the overall customer experience.

Key Features of Inventory Management Software

Inventory management software is a powerful tool that can help businesses of all sizes manage their inventory more effectively. Key features of inventory management software include:

Real-time Inventory Tracking

Real-time inventory tracking allows businesses to see how much of each item they have in stock at any given time. This information can be used to make informed decisions about purchasing, production, and shipping. Real-time inventory tracking can also help businesses avoid overstocking or understocking, which can lead to lost sales or wasted inventory.

Purchase Order Management

Purchase order management allows businesses to track the status of their purchase orders. This information can be used to ensure that orders are being processed correctly and that goods are being delivered on time. Purchase order management can also help businesses to negotiate better prices with suppliers.

Reporting Capabilities

Reporting capabilities allow businesses to generate reports on their inventory levels, sales, and other metrics. This information can be used to identify trends and make better decisions about inventory management. Reporting capabilities can also help businesses to comply with regulatory requirements.

Types of Inventory Management Software

Inventory management software is available in various types, each tailored to specific business needs and industries. Understanding the different types of software can help businesses select the most suitable solution for their operations.

Cloud-Based Inventory Management Software

Cloud-based inventory management software is hosted on remote servers, accessible through an internet connection. It offers advantages such as:

- Accessibility from anywhere with an internet connection

- Automatic updates and maintenance

- Cost-effectiveness due to subscription-based pricing

Businesses that benefit from cloud-based software include:

- E-commerce businesses with distributed inventory

- Businesses with multiple locations or remote teams

- Businesses seeking a flexible and scalable solution

On-Premise Inventory Management Software

On-premise inventory management software is installed on a local server within the business premises. It provides greater control and customization, but also requires:

- In-house IT infrastructure and maintenance

- Higher upfront investment

- Limited accessibility outside the business network

Businesses that benefit from on-premise software include:

- Businesses with complex inventory requirements

- Businesses with sensitive data that require high security

- Businesses with large or rapidly changing inventory

Hybrid Inventory Management Software

Hybrid inventory management software combines cloud-based and on-premise capabilities, offering a balance of flexibility and control. It allows businesses to:

- Store critical data on-premise for security

- Access inventory information remotely through the cloud

- Customize the software to meet specific needs

Businesses that benefit from hybrid software include:

- Businesses with a mix of physical and online inventory

- Businesses with a need for both flexibility and customization

- Businesses with regulatory or compliance requirements

Industry-Specific Inventory Management Software

Industry-specific inventory management software is designed to meet the unique requirements of specific industries, such as:

- Retail: Software tailored for managing retail inventory, including POS systems

- Manufacturing: Software designed for managing raw materials, work-in-progress, and finished goods

- Healthcare: Software optimized for tracking medical supplies, equipment, and pharmaceuticals

Businesses in these industries benefit from using software that is tailored to their specific operational processes and regulatory requirements.

Choosing the Right Inventory Management Software

Selecting the right inventory management software is crucial for businesses to optimize their operations and maximize profitability. Consider the following factors to make an informed decision:

Business Size and Industry

The size and industry of your business significantly influence your software needs. Small businesses may require a basic system with core functionalities, while larger enterprises need comprehensive solutions with advanced features. Different industries have unique inventory management requirements, such as temperature control for perishable goods or tracking for serialized items.

Specific Needs

Identify your specific inventory management challenges and requirements. Consider factors such as the number of SKUs, inventory turnover rate, and the need for real-time visibility or integration with other systems. Clearly defining your needs will help you narrow down the software options that meet your unique requirements.

Step-by-Step Guide to Selecting the Right Software

- Define Your Requirements: Determine your specific inventory management needs based on business size, industry, and operational challenges.

- Research and Compare Options: Explore different software vendors and their offerings. Compare features, pricing, customer reviews, and industry expertise.

- Request Demos and Trial Versions: Experience the software firsthand through demos or trial versions. This allows you to evaluate its functionality and user-friendliness.

- Consider Integration and Scalability: Ensure the software can integrate with your existing systems and support future growth. Scalability is crucial for businesses planning to expand or increase inventory volume.

- Seek Expert Advice: If needed, consult with industry experts or software consultants to gain insights and recommendations based on your specific business context.

- Make an Informed Decision: Evaluate all the factors and select the software that best aligns with your requirements and long-term goals.

Implementing Inventory Management Software: Inventory Software For Business

Implementing inventory management software can significantly enhance inventory management processes, but it also requires careful planning and execution. Here’s an overview of the implementation process, along with potential challenges and tips for success:

Flowchart Illustrating Implementation Steps

The following flowchart provides a visual representation of the steps involved in implementing inventory management software:

“`

Plan

|

V

Assess Current System

|

V

Identify Software Needs

|

V

Select and Purchase Software

|

V

Implement Software

|

V

Train Staff

|

V

Monitor and Evaluate

“`

Challenges During Implementation

Businesses may encounter various challenges during the implementation process, including:

- Data migration and accuracy

- Integration with existing systems

- User adoption and training

- Process changes and workflow disruptions

- Budget and resource constraints

Tips for Ensuring Successful Implementation

To ensure a successful implementation, consider the following tips:

- Define clear project goals and objectives.

- Thoroughly assess your current inventory management system.

- Involve key stakeholders and users in the selection process.

- Provide comprehensive training and support to users.

- Plan for data migration and system integration carefully.

- Establish a dedicated implementation team.

- Monitor and evaluate the system’s performance regularly.

- Continuously improve and optimize the system based on user feedback.

By following these steps and considering the challenges and tips discussed above, businesses can effectively implement inventory management software and reap its numerous benefits.

Best Practices for Inventory Management

Effective inventory management is crucial for businesses to optimize their operations, reduce costs, and enhance customer satisfaction. Implementing best practices can help businesses streamline their inventory processes, improve accuracy, and gain valuable insights.

Key best practices include:

Just-in-Time Inventory

Just-in-time (JIT) inventory is a method where businesses receive inventory as close as possible to the time it is needed for production or sale. This minimizes storage costs, reduces waste, and improves cash flow.

Safety Stock Levels

Safety stock is an additional inventory held to buffer against unexpected demand fluctuations or supply chain disruptions. Determining optimal safety stock levels requires careful analysis of historical data and demand forecasting.

Inventory Forecasting

Inventory forecasting involves predicting future demand based on historical data, market trends, and other factors. Accurate forecasting helps businesses plan production, avoid stockouts, and optimize inventory levels.

Case Studies and Success Stories

Inventory management software has proven its worth in streamlining operations and boosting profitability for businesses across various industries. To illustrate its impact, let’s delve into case studies that showcase the tangible benefits organizations have reaped from implementing these solutions.

Retail Industry

- Case Study: ABC Retail Chain

- Implemented an inventory management system that integrated with POS and e-commerce platforms.

- Achieved a 15% reduction in inventory carrying costs through optimized stock levels.

- Improved customer satisfaction by ensuring product availability and reducing out-of-stocks.

- Key Takeaway: Integration with other business systems enhances data accuracy and efficiency.

Manufacturing Industry

- Case Study: XYZ Manufacturing

- Deployed an inventory management system to track raw materials, work-in-progress, and finished goods.

- Reduced production lead times by 20% through improved visibility and control over inventory.

- Enhanced collaboration between production, procurement, and warehouse teams.

- Key Takeaway: Real-time inventory data empowers informed decision-making.

Healthcare Industry

- Case Study: HealthCo Hospital

- Implemented an inventory management system for medical supplies, equipment, and pharmaceuticals.

- Reduced inventory waste by 10% through accurate tracking and forecasting.

- Improved patient safety by ensuring the availability of critical medical supplies.

- Key Takeaway: Inventory management is crucial for maintaining efficient and compliant healthcare operations.

Future Trends in Inventory Management Software

The future of inventory management software is shaped by emerging technologies that enhance efficiency, accuracy, and visibility across supply chains. These trends empower businesses to optimize inventory levels, reduce costs, and improve customer satisfaction.

One significant trend is the adoption of artificial intelligence (AI) and machine learning (ML) algorithms. These technologies automate inventory management tasks, such as demand forecasting, replenishment planning, and inventory optimization. By analyzing historical data and real-time insights, AI-powered systems provide data-driven recommendations and predictive analytics, enabling businesses to make informed decisions.

Integration with Other Systems, Inventory software for business

Inventory management software is increasingly integrated with other enterprise systems, such as enterprise resource planning (ERP) and customer relationship management (CRM) systems. This integration streamlines data sharing, eliminates manual data entry, and provides a comprehensive view of inventory and customer information. It enhances collaboration and coordination among different departments, resulting in improved inventory accuracy and reduced lead times.

Real-Time Tracking and Visibility

Real-time tracking and visibility are becoming essential for efficient inventory management. Radio frequency identification (RFID) technology and sensor-based systems provide real-time data on inventory levels, location, and movement. This enables businesses to track inventory throughout the supply chain, from raw materials to finished goods, improving inventory accuracy and reducing shrinkage.

Predictive Analytics

Predictive analytics capabilities are increasingly incorporated into inventory management software. These tools leverage historical data and advanced algorithms to forecast demand, identify trends, and predict future inventory needs. By anticipating demand patterns, businesses can optimize inventory levels, reduce overstocking and stockouts, and improve customer service.

Cloud-Based Solutions

Cloud-based inventory management software offers flexibility, scalability, and cost-effectiveness. These solutions eliminate the need for on-premises infrastructure, reduce IT costs, and provide access to real-time inventory data from anywhere, anytime. Cloud-based systems also facilitate collaboration among multiple users and locations, enabling seamless inventory management across distributed supply chains.

How to Prepare for These Changes

To prepare for these future trends, businesses should consider the following steps:

- Evaluate current inventory management processes and identify areas for improvement.

- Research and select inventory management software that aligns with business needs and emerging trends.

- Implement the software and train staff on its use.

- Monitor inventory data and adjust inventory management strategies as needed.

- Continuously evaluate the latest inventory management trends and technologies to stay competitive.

Last Point

In conclusion, inventory software for business is an indispensable tool for companies seeking to optimize their operations, reduce costs, and enhance customer satisfaction. By embracing the power of these innovative solutions, businesses can gain a competitive edge, streamline their supply chains, and unlock new opportunities for growth.

FAQ Corner

What are the key benefits of using inventory software for business?

Inventory software for business offers numerous benefits, including cost savings, improved efficiency, reduced waste, and enhanced customer satisfaction.

How can inventory software help businesses reduce costs?

Inventory software helps businesses reduce costs by optimizing inventory levels, minimizing waste, and streamlining purchasing processes.

What are the key features to look for in inventory software?

Key features to consider include real-time inventory tracking, purchase order management, reporting capabilities, and integration with other business systems.